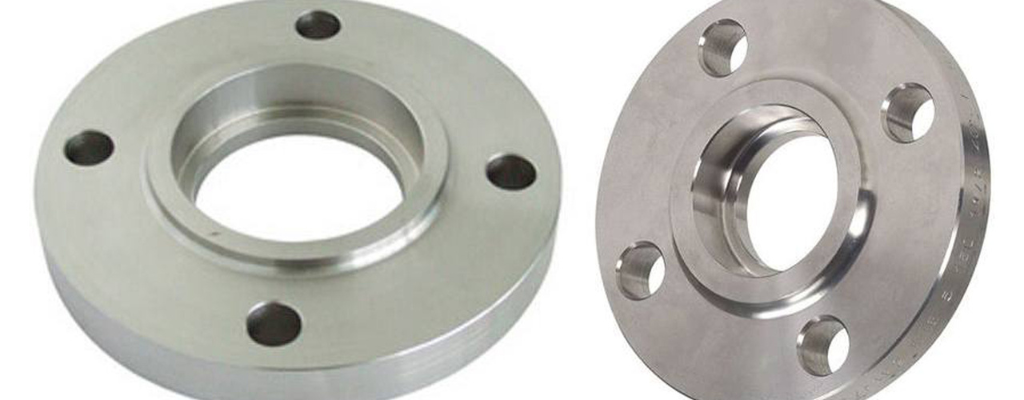

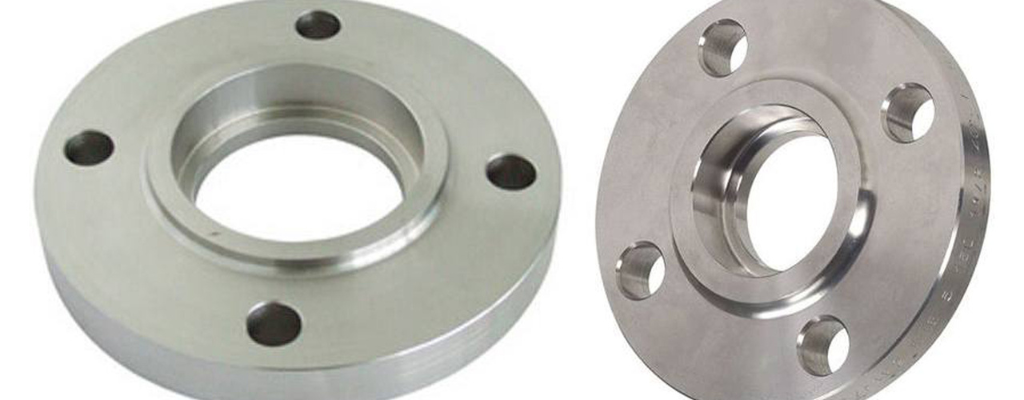

A socket weld flange is a flange that is used to join pipes together by welding. It has a female hole on one end and a flat, machined surface on the other for bolting to another flange or equipment. Socket weld flanges are often used in small-diameter, high-pressure pipe systems because they make a strong link that doesn’t leak. Socket weld flanges are made to connect two pipes powerfully and safely. The pipe fits into the hole on one end of the flange, while the flat surface on the other is where the bolts are attached. This setup ensures the seal is tight and reliable, so there is less chance of leaks in high-pressure situations. One of the best things about socket weld flanges is that they can work with high pressure. The welding method used to connect the pipe to the flange adds more support and strengthens the joint. It makes socket weld flanges good for systems at high pressures and temperatures, like those in the oil and gas, chemical, industrial, and power generation industries.

A socket weld flange’s internal socket is useful in several ways. First, it makes it easier for fluids to move smoothly by reducing the amount of turbulence and pressure drop in the piping system. It can be helpful when the flow rate and speed are very important. Second, the internal socket makes it easy to line up the pipe during fitting so that it can be welded in the right place. It also leaves room for welding, creating a strong and long-lasting link. Socket weld plates come in different materials and can be used for different tasks. Carbon steel, stainless steel, and alloy steel are all common materials. The choice of material depends on how it will be used, how resistant it needs to be to rust, and how well it works with the fluid being moved. For example, stainless steel socket weld flanges are often used when toxic substances are involved, while carbon steel flanges can be used for various tasks. When using socket weld flanges, you must consider how the welding will be done. Socket weld parts need to be welded with skill and accuracy to ensure they are done right and are strong. Fillet welding is used to join the pipe to the socket end of the flange during the welding process. This process can take a long time and needs welders with a lot of experience. It is important to follow welding standards and rules to get high-quality welds that are free of flaws.

Socket weld flanges are often used for pipes with 1/2 inch and 4 inches diameters. Because they are small and can seal well, they are especially good for pipes with smaller diameters. But other flanges, like slip-on or weld neck flanges, may be better for bigger pipe sizes. When it comes to price, socket weld flanges are cheaper than some other types of flanges. But it’s important to consider the total installation cost, which includes welding work and time. For socket weld flanges, a trained welder must carefully plan, align, and do the welding process. It can make the installation take longer and cost more. In short, socket weld flanges are often used in high-pressure pipe systems with small diameters. They make a strong link that doesn’t leak through the welding process. They also have benefits like increased strength, smooth fluid flow, and easy alignment. Socket weld flanges are often used in the oil and gas, chemical, petrochemical, and power generation businesses.

Socket Weld Flange Specifications

Dimensions : ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Size : 1/2″ (15 NB) to 48″ (1200NB)

Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673

BS : BS4504 , BS4504, BS1560, BS10

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Material & Grades of Socket Weld Flange

Stainless Steel Socket weld Flanges :

ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Duplex & Super Duplex Steel Socket weld Flanges :

ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Carbon Steel Socket weld Flanges :

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706

Low Temperature Carbon Steel Socket weld Flanges : ASTM A350, LF2, LF3

Alloy Steel Socket weld Flanges :

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Copper Alloy Steel Socket weld Flanges : ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

Nickel Alloy Socket weld Flanges :

ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020)

Other Products & Grade

Stainless Steel 304 Pipes & Tubes

Stainless Steel 304L Pipes & Tubes

Stainless Steel 304H Pipes & Tubes

Stainless Steel 310s Pipes & Tubes

Stainless Steel 316 Pipes & Tubes

Stainless Steel 316L Pipes & Tubes

Stainless Steel 316H Pipes & Tubes

Stainless Steel 316Ti Pipes & Tubes

Stainless Steel 317/317L Pipes & Tubes

Stainless Steel 321/321H Pipes & Tubes

Stainless Steel 347/347H Pipes & Tubes

Stainless Steel 904L Pipes & Tubes

Stainless Steel 309 Pipes & Tubes

Stainless Steel 202 Pipes & Tubes

Stainless Steel 304 Sheets, Plates & Coils

Stainless Steel 304L Sheets, Plates & Coils

Stainless Steel 304H Sheets, Plates & Coils

Stainless Steel 310s Sheets, Plates & Coils

Stainless Steel 316 Sheets, Plates & Coils

Stainless Steel 316L Sheets Plates Coils

Stainless Steel 316H Sheets, Plates & Coils

Stainless Steel 316Ti Sheets, Plates & Coils

Stainless Steel 317/317L Sheets, Plates & Coils

Stainless Steel 321/321H Sheets, Plates & Coils

Stainless Steel 347/347H Sheets, Plates & Coils

Stainless Steel 904L Sheets, Plates & Coils

Stainless Steel 202 Sheets, Plates & Coils

Stainless Steel 420 Sheets, Plates & Coils

Stainless Steel 431 Sheets, Plates & Coils

Stainless Steel 431H Sheets, Plates & Coils

Stainless Steel 410 Sheets, Plates & Coils

Stainless Steel 410 Sheets, Plates & Coils

Stainless Steel 304 Flats Angles

Stainless Steel 304L Flats Angles

Stainless Steel 304H Flats Angles

Stainless Steel 310s Flats Angles

Stainless Steel 316 Flats Angles

Stainless Steel 316L Flats Angles

Stainless Steel 316H Flats Angles

Stainless Steel 316Ti Flats Angles

Stainless Steel 317/317L Flats Angles

Stainless Steel 321/321H Flats Angles

Stainless Steel 347/347H Flats Angles

Stainless Steel 904L Flats Angles

Stainless Steel 202 Flats Angles

Stainless Steel 304 Circle RIngs

Stainless Steel 304L Circle RIngs

Stainless Steel 304H Circle RIngs

Stainless Steel 310s Circle RIngs

Stainless Steel 316 Circle RIngs

Stainless Steel 316L Circle RIngs

Stainless Steel 316H Circle RIngs

Stainless Steel 316Ti Circle RIngs

Stainless Steel 317/317L Circle RIngs

Stainless Steel 321/321H Circle RIngs

Stainless Steel 347/347H Circle RIngs

Stainless Steel 904L Circle RIngs

Stainless Steel 202 Circle RIngs

Stainless Steel 304 Pipe Fittings

Stainless Steel 304L Pipe Fittings

Stainless Steel 304H Pipe Fittings

Stainless Steel 310s Pipe Fittings

Stainless Steel 316 Pipe Fittings

Stainless Steel 316L Pipe Fittings

Stainless Steel 316H Pipe Fittings

Stainless Steel 316Ti Pipe Fittings

Stainless Steel 317/317L Pipe Fittings

Stainless Steel 321/321H Pipe Fittings

Stainless Steel 347/347H Pipe Fittings

Stainless Steel 904L Pipe Fittings

Stainless Steel 304 Forged Fittings

Stainless Steel 304L Forged Fittings

Stainless Steel 304H Forged Fittings

Stainless Steel 310s Forged Fittings

Stainless Steel 316 Forged Fittings

Stainless Steel 316L Forged Fittings

Stainless Steel 316H Forged Fittings

Stainless Steel 316Ti Forged Fittings

Stainless Steel 317/317L Forged Fittings

Stainless Steel 321/321H Forged Fittings

Stainless Steel 347/347H Forged Fittings

Stainless Steel 904L Forged Fittings

Stainless Steel 304 Flanges

Stainless Steel 304L Flanges

Stainless Steel 304H Flanges

Stainless Steel 310s Flanges

Stainless Steel 316 Flanges

Stainless Steel 316L Flanges

Stainless Steel 316H Flanges

Stainless Steel 316Ti Flanges

Stainless Steel 317/317L Flanges

Stainless Steel 321/321H Flanges

Stainless Steel 347/347H Flanges

Stainless Steel 904L Flanges

Stainless Steel 304 SOFT AND HARD Wire

Stainless Steel 304L SOFT AND HARD Wire

Stainless Steel 304H SOFT AND HARD Wire

Stainless Steel 310s SOFT AND HARD Wire

Stainless Steel 316 SOFT AND HARD Wire

Stainless Steel 316L SOFT AND HARD Wire

Stainless Steel 316H SOFT AND HARD Wire

Stainless Steel 316Ti SOFT AND HARD Wire

Stainless Steel 317/317L SOFT AND HARD Wire

Stainless Steel 321/321H SOFT AND HARD Wire

Stainless Steel 347/347H SOFT AND HARD Wire

Stainless Steel 904L SOFT AND HARD Wire

Stainless Steel 202 SOFT AND HARD Wire

Stainless Steel 304 Round Bars

Stainless Steel 304L Round Bars

Stainless Steel 304H Round Bars

Stainless Steel 310s Round Bars

Stainless Steel 316 Round Bars

Stainless Steel 316L Round Bars

Stainless Steel 316H Round Bars

Stainless Steel 316Ti Round Bars

Stainless Steel 317/317L Round Bars

Stainless Steel 321/321H Round Bars

Stainless Steel 347/347H Round Bars

Stainless Steel 904L Round Bars

Stainless Steel 202 Round Bars

Stainless Steel Compression Fittings

Stainless Steel Pneumatic Fittings

Stainless Steel Hydraulic Hose Fittings

Stainless Steel Blocks

Stainless Steel Pressure Gauges

Stainless Steel Nozzles

Stainless Steel Shells

Stainless Steel Flexible Hose

Stainless Steel Rotameter

Stainless Steel Flexican Bellows

Stainless Steel Valves

Stainless Steel Fasteners

Stainless Steel Haxagonal Bars

Stainless Steel Square Bars

A106 Gr.B Pipes & Tubes

IS 1239 Pipes & Tubes

Inconel 600 Pipes and Tubes

Inconel 601 Pipes and Tubes

Inconel 617 Pipes and Tubes

Inconel 625 Pipes and Tubes

Inconel 690 Pipes and Tubes

Inconel 718 Pipes and Tubes

Inconel X-750 Pipes and Tubes

Incoloy Alloy DS Pipes & Tubes

Inconel 800 Pipes and Tubes

Inconel 825 Pipes and Tubes

Inconel 600 Sheets, Plates & Coils

Inconel 601 Sheets, Plates & Coils

Inconel 617 Sheets, Plates & Coils

Inconel 625 Sheets, Plates & Coils

Inconel 690 Sheets, Plates & Coils

Inconel 718 Sheets, Plates & Coils

Inconel X-750 Sheets, Plates & Coils

Incoloy Alloy DS Sheets, Plates Coils

Inconel 800 Sheets, Plates & Coils

Inconel 825 Sheets, Plates & Coils

Inconel 600 Round Bars

Inconel 601 Round Bars

Inconel 617 Round Bars

Inconel 625 Round Bars

Inconel 690 Round Bars

Inconel 718 Round Bars

Inconel X-750 Round Bars

Incoloy Alloy DS Round Bars

Incoloy 800 Round Bars

Inconel 825 Round Bars

Inconel Buttweld Fittings

Inconel Forged Fittings

Inconel Flanges

Inconel Fasteners

Hastelloy C276 Pipes & Tubes

Hastelloy C22 Pipes & Tubes

Hastelloy B2 Pipes & Tubes

Hastelloy B3 Pipes & Tubes

Hastelloy X Pipes & Tubes

Hastelloy C276 Sheets,Plates & Coils

Hastelloy C22 Sheets,Plates & Coils

Hastelloy B2 Sheets,Plates & Coils

Hastelloy B3 Sheets,Plates & Coils

Hastelloy X Sheets,Plates & Coils

Hastelloy C276 Round Bars

Hastelloy C22 Round Bars

Hastelloy B2 Round Bars

Hastelloy B3 Round Bars

Hastelloy X Round Bars

Hastelloy Buttweld Fittings

Hastelloy Forged Fittings

Hastelloy Flanges

Hastelloy Fasteners

Titanium Gr 2 Tubes

Titanium Gr 5 Pipes

CP Titanium Grade 7 Pipes & Tubes

Titanium Grade 11 Pipes & Tubes

Titanium Grade 12 Pipes & Tubes

Titanium Gr 2 Sheets, Plates & Coils

Titanium Gr 5 Sheets, Plates & Coils

Titanium Grade 7 Sheets, Plates & Coils

Titanium Grade 11 Sheets, Plates & Coils

Titanium Grade 12 Sheets, Plates & Coils

Titanium Gr 2 Round Bars

Titanium Gr 5 Round Bars

CP Titanium Grade 7 Round Bars

Titanium Grade 11 Round Bars

Titanium Grade 12 Round Bars

Titanium Butt weld Fittings

Titanium Forged Fittings

Titanium Flanges

Titanium Fasteners

Duplex Steel UNS S31803 Pipes & Tubes

Duplex Steel UNS S32205 Pipes & Tubes

Duplex Steel S31803 Sheets, Plates & Coils

Duplex Steel S32205 Sheets, Plates & Coils

Duplex Steel S31803 Round Bars

Duplex Steel S32205 Round Bars

Duplex Steel Buttweld Fittings

Duplex Steel Forged Fittings

Duplex Steel Flanges

Duplex Steel Fasteners

Super Duplex Steel UNS S32550 Pipes & Tubes

Super Duplex Steel UNS S32750 Pipes & Tubes

Super Duplex Steel UNS S32760 Pipes & Tubes

Super Duplex Steel UNS S32550 Sheets, Plates & Coils

Super Duplex Steel UNS S32750 Sheets, Plates & Coils

Super Duplex Steel UNS S32760 Sheets, Plates & Coils

Super Duplex Steel UNS S32550 Round Bars

Super Duplex Steel F53 Round Bars (UNS S32750)

Super Duplex Steel F55 Round Bars (UNS S32760)

Super Duplex Steel Buttweld Fittings

Super Duplex Steel Forged Fittings

Super Duplex Steel Flanges

Super Duplex Steel Fasteners

Male Connector

Female Connector

BulkHead Male Connector

BulkHead Female Connector

Plain Connector

Nut

Single Ferrule

Double Ferrule

Front Ferrule

Back Ferrule

Coupling Cap

Tube End Closure

Fitting End Closure

Weldable Male Connector (SW)

O Seal Male Connector

Female Manometer Connector

Butt Weld Pipe Connector

Socket Weld Tube Connector

Mild steel Pipes and Tubes

Carbon Steel Pipes and Tubes

Alloy Steel Pipes and Tubes

Galvanise Pipe

Mild Steel Sheet Plate Coil

Alloy Steel Plates

Alloy Steel Pipes

Gi Sheet Plate Coil

SA387 Gr 11 Class 1 Plate

SA387 Gr 22 Class 1 Plate

SA387 Gr 11 Class 2 Plate

SA387 Gr 22 Class 2 Plate

ASTM A179 Pipes & Tubes

ASTM A192 Pipes & Tubes

ASTM A210 Pipes & Tubes

ASTM A213 Pipes & Tubes

Equal Tee

Unequal Teel

Male Branch Tee

Female Branch Tee

Male (Hex Body)

Female (Hex Body)

Female Tee (Round Body Threaded )

Female Tee (Round Body Socket weld)

Street Tee (Hex Body)

Street Tee (Round Body SW)

Branch Tee (Hex Body)

Branch Tee (Round Body SW)

Union Tee

Reducing Union Tee

Male Run Tee

Positionable Male Run Tee

Positionable Branch Tee

Positionable Male Branch Tee

Female Run Tee

Male Elbow

Female Elbow

Union Elbow

Buld Head Union Elbow

Male Elbow (Hex Body)

Female Elbow (Hex Body)

Female Elbow (Round Body Threaded)

Female Elbow (Round Body SW)

Street Elbow (Hex Body)

Female Cross (Hex Body)

Female (Round Body TH)

Union Cross

45 Deg Male Elbow

45 Deg Positionable Elbow

Butt Weld Elbow Pipe

Socket Weld Tube Elbow

BS 3059 Pipes & Tubes

IS 2062 Plate

SA516 Gr70 Plate

SA210 Tubes Gr.A1

IS3589 Pipes

LSAW & HSAW Pipes

A333 Pipes

A335 Pipes

ASTM A671 Pipes & Tubes

ASTM A672 Pipes & Tubes

IS 4923 Square Pipe

YST 310 Square Pipe

Gi Pipe

Stainless Steel Gate Valve

Stainless Steel Ball Valve

Cast Steel Iron Valve

Butterfly Valve

Carbon Steel Gate Valve